The

Automation System

(May 2022 - Sep 2022)

This is my first engineering internship and I was responsible for brainstorming a solution to improve the changeover of the production process by using an automation system known as Karakuri in Japanese. I used my engineering knowledge in this project to conceptualize 3D design, material selection, installation, and system test runs.

ExplorePROBLEM STATEMENT

The Company wants to create an automation system that can support operators in the packing station of the assembly line. A few problems need to be solved using the system: improving the operator's working ergonomics, convenience, and comfort. Also, the system should help save downtime by swapping container during the packaging process and using spare time to produce more products.

Project Target

Research and Analysis

To design a system that fits a variety of products, I must have a good understanding of the product's type, size, and material. I collected all critical information about each product and its variation and analyzed it to find the design's common trait.

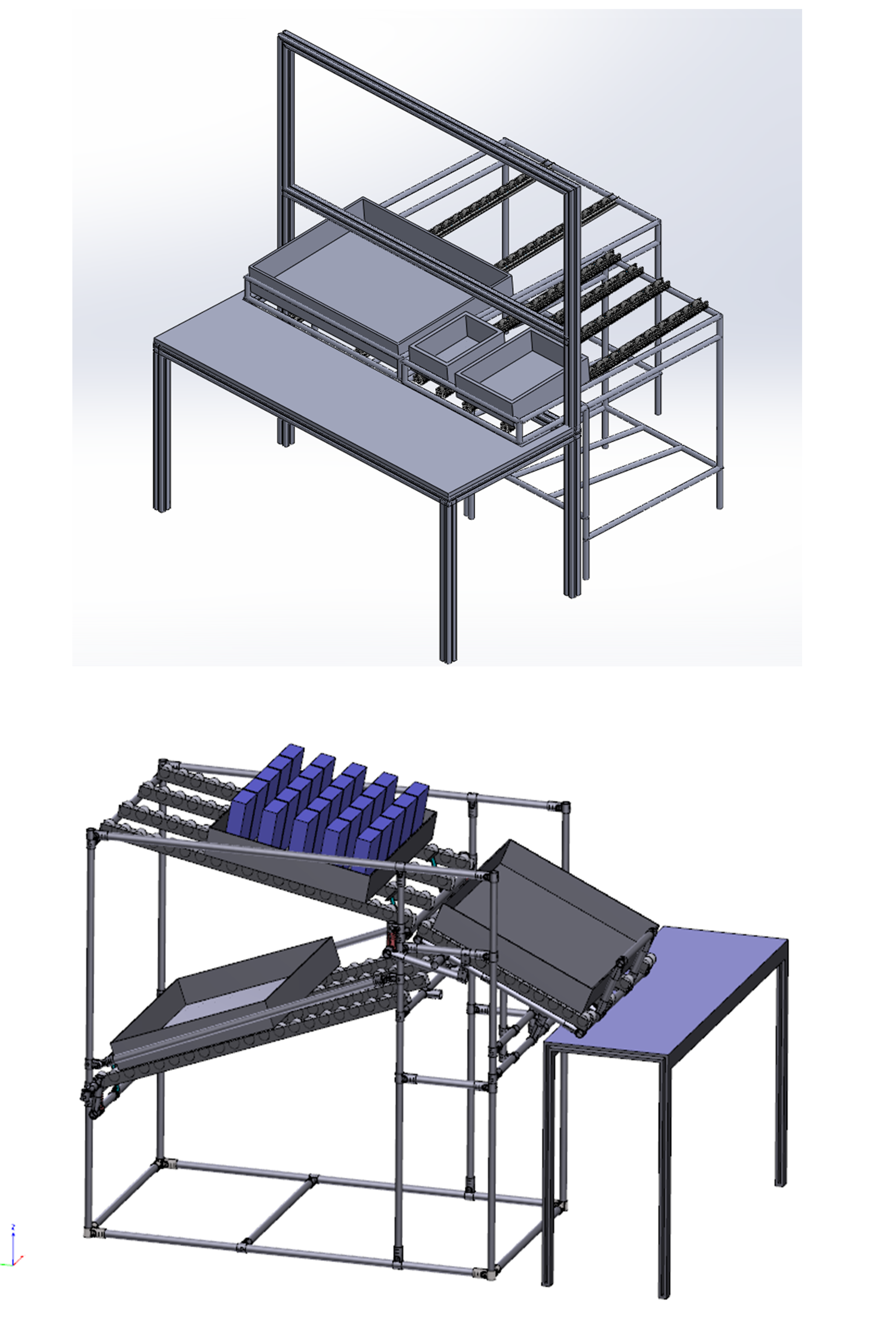

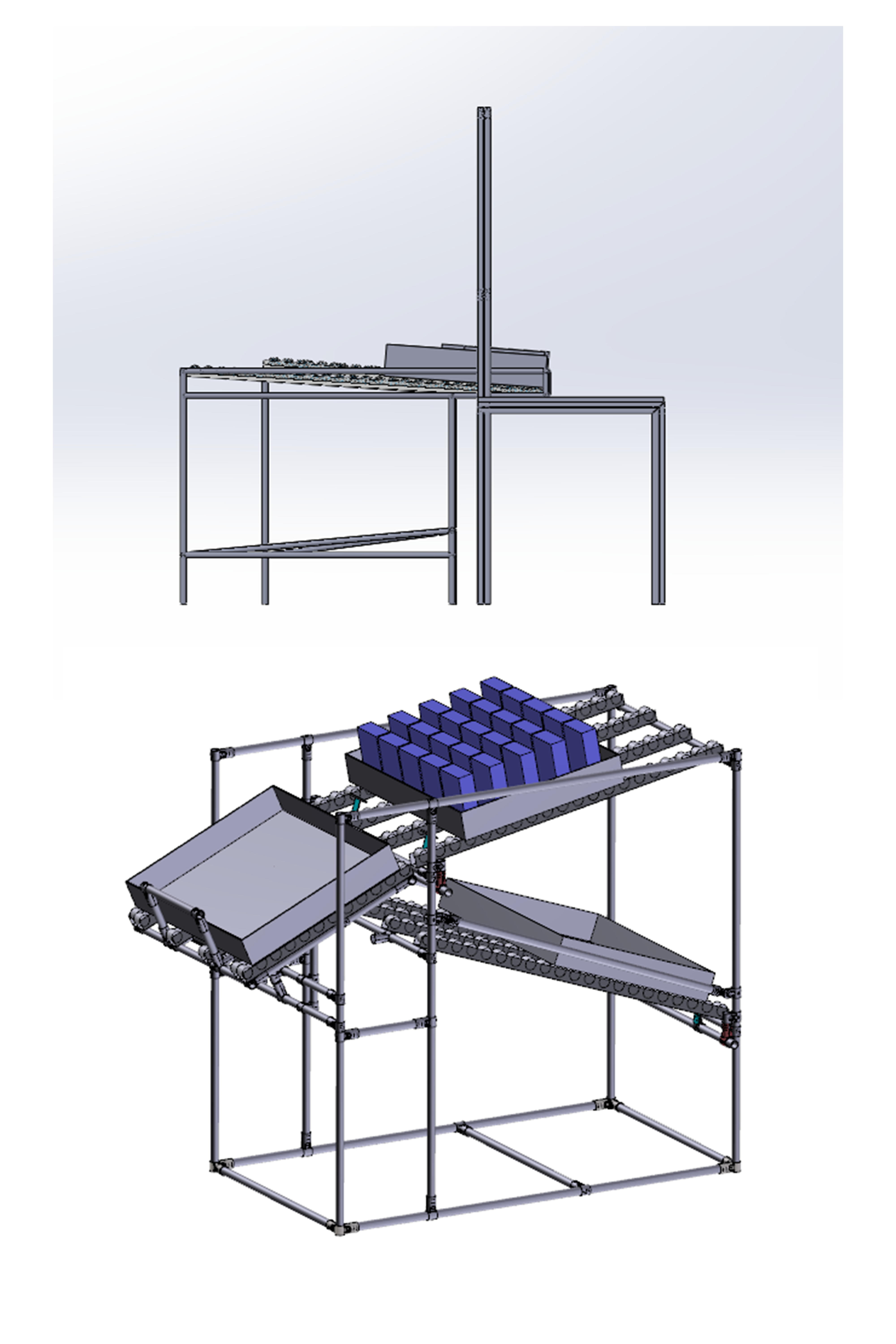

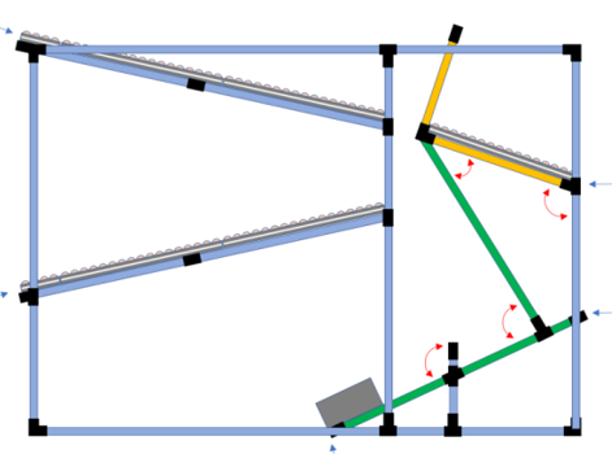

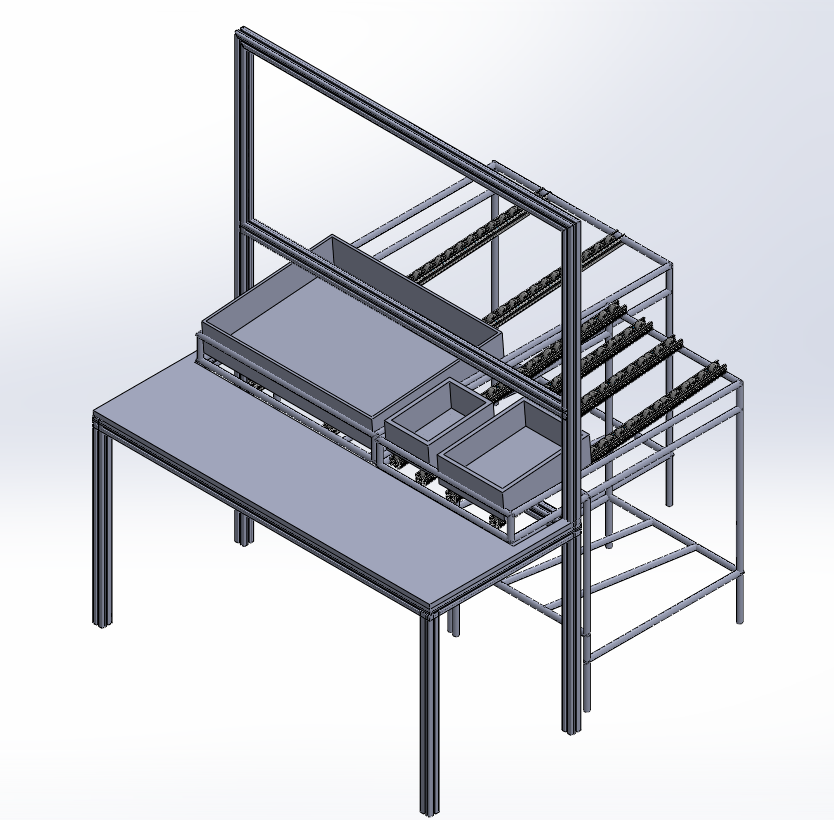

3D design

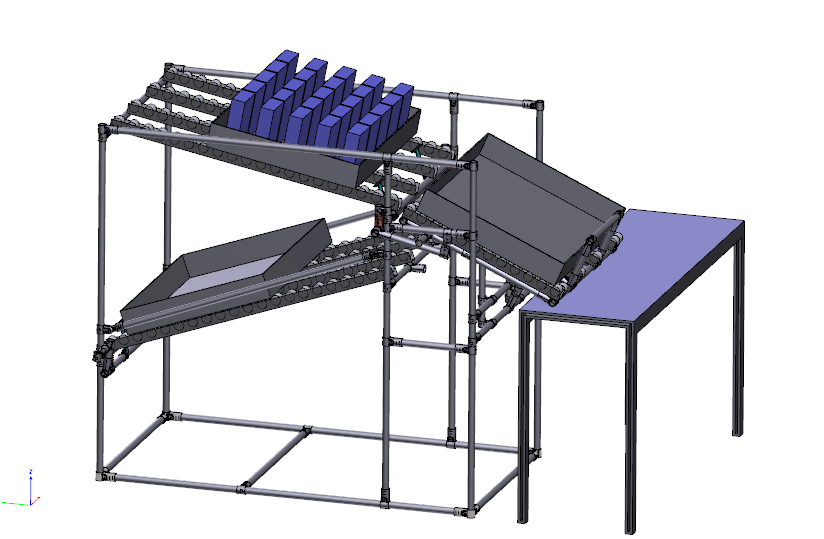

To get the best visualization of the system, they need to be simulated through 3D software like Creo and SolidWorks. I used the 3D design to explain my idea to colleagues and managers to get their feedback.

Test Run and Installation

All new improvements need to be tested to evaluate effectiveness, and my design has also gone through many reviews. In the end, being installed and put into mass use is the project's success.

Steps

1. Collect and Analyze data

Each function in the company will

keep different information about the product

Collecting such a data to analyze and

generate the design for the system is priority.

2. 3D design of the system

With all the reference data of the product,

I have to propose a 3D design of the

system that fits most of the

production good in the plant.

3. Assembly and Installation

Based on the 3D drawing of the system,

the system will be built and do a test

run for the pilot line. The success

of that production line will be replicated

to the entire factory.

4. Evaluate the effectiveness

Evaluate the quality and effectiveness

of the automation system design for the

pilot line. The success of that pilot

line will be replicated to the entire factory.

My Approach

June 2022

The two design and 3D printed of them

The Beginning

I started by collecting information about the products produced in that line. There are over 16 lines in the plant and over 2000 variations of the products. One of the project's challenges is gathering all that information and filtering out the most important one for the system design. I soon picked up some critical information I needed, such as the product's size, family, and packages.

The Process

The system's design must be based on that data so no one will be able to challenge that design. I sketched out my desired shape and made a 3D drawing of the system. I had to present and communicate the design with the review team many times, and the final one took almost 2 months to complete.

The Result

After the final design is approved, the installation and performance are quickly completed within the next month. Finally, the evaluation is complete, and the company invests in my project because the system has reduced 30 minutes of downtime per day and $400.000 a year in revenue savings.